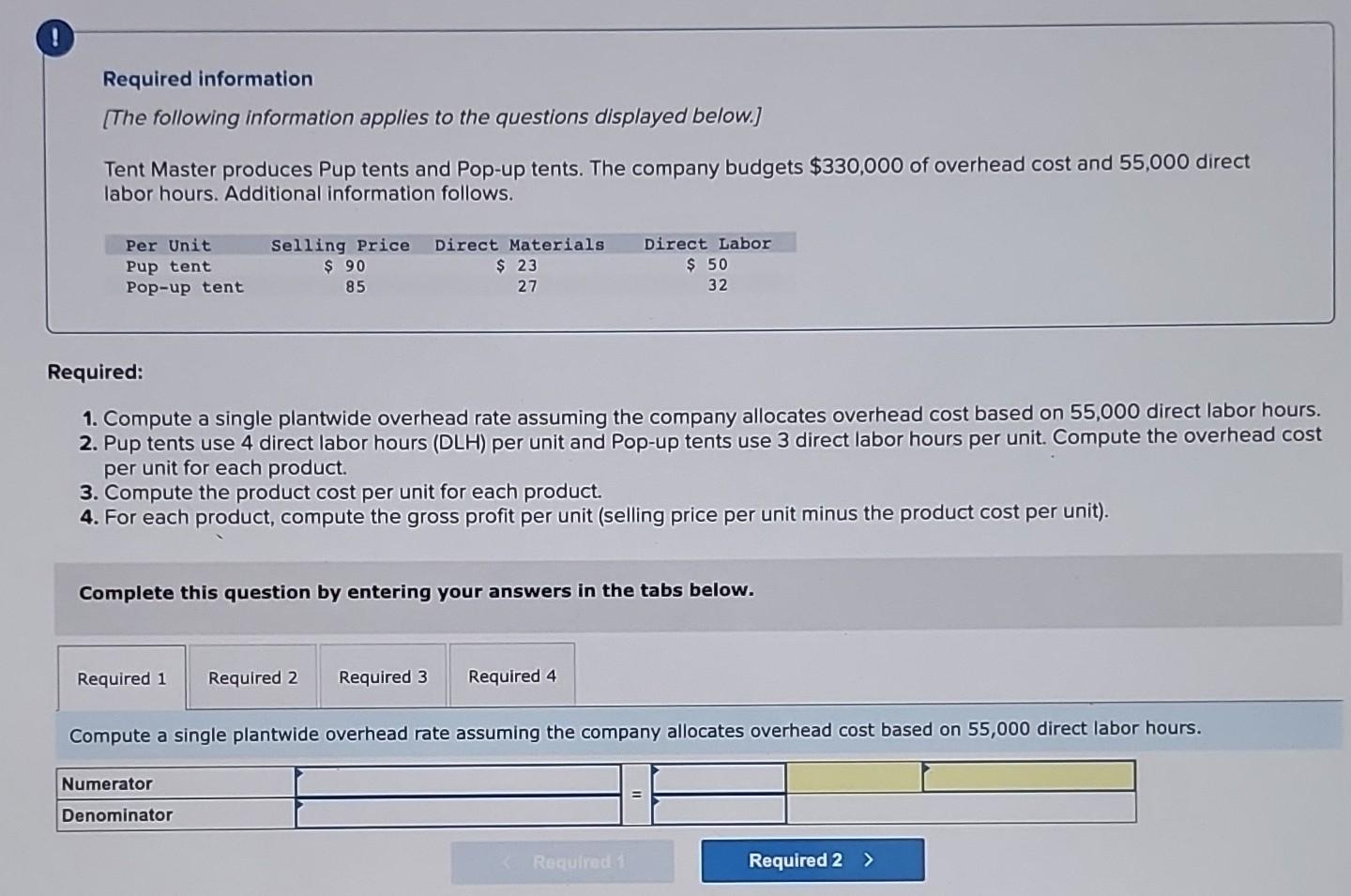

This overhead allocation method finds its place in very small entities with a minimized or simple cost structure. Regardless of the approach used to allocateoverhead, a predetermined overhead rate is established for eachcost pool. The plantwide allocation approach uses one cost pool tocollect and apply overhead costs and therefore uses onepredetermined overhead rate for the entire company. The departmentallocation approach uses several cost pools (one for eachdepartment) and therefore uses several predetermined overheadrates.

Enhanced Profitability through Informed Pricing

Notice that the total gross profit remains the same no matter how we allocated fixed manufacturing overhead to product lines. To experience the robust capabilities of Sourcetable, including ease of use in calculating complex rates like the plantwide overhead rate, visit app.sourcetable.com/signup to try it for free. Sourcetable, an AI-powered spreadsheet, transforms this calculation from a tedious task into a seamless process.

Allocating Based on Direct Labor

We’ll study how this works in the next section, but first check your understanding of using a single rate to allocate fixed manufacturing overhead to products. By following these clear and precise steps and understanding the necessary components, businesses can effectively calculate the plantwide overhead rate, facilitating better financial management and operational efficiency. On this page, you’ll discover the steps required to calculate the plantwide overhead rate and the potential implications on your business’s financial health. We’ll explore how Sourcetable lets you calculate this and more using its AI-powered spreadsheet assistant, which you can try at app.sourcetable.com/signup. Both plantwide rate and departmental rate are means of estimating the overhead cost allocation to products and services. However, there are a few points of differences that make each preferable by firms as per their requirements and suitability.

- This section provides practical examples to illustrate the computation process.

- Proceed by dividing the total overhead by the total direct labor hours to get the overhead rate per hour.

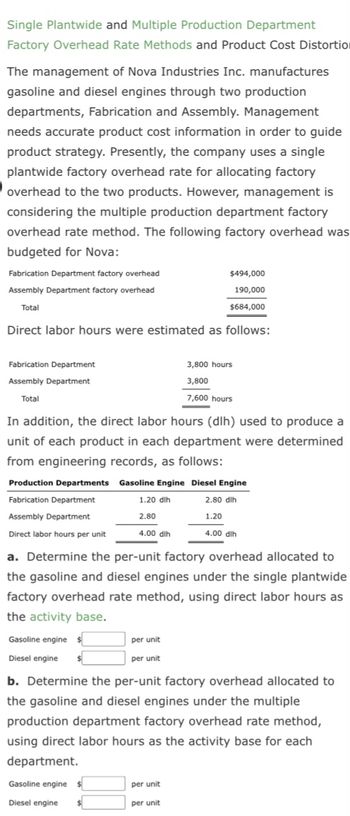

- This approach typically provides moreaccurate cost information than simply using one plantwide rate butstill relies on the assumption that overhead costs are driven bydirect labor hours, direct labor costs, or machine hours.

Product Costs Using the Plantwide Allocation Approach at

In that case, we might choose to allocate fixed overhead based on direct labor hours (DLH) or direct labor dollars (DL$). If our standard direct labor cost is the same for both purses, these two calculations will produce the same results, so in this lesson, we’ll use DL$. However, if workers producing deluxe purses are more highly paid than workers producing basic purses, the outcome between the two direct labor methods would be different. The choice of an allocation method depends on how managersdecide to group overhead costs and the desired accuracy of productcost information. For example, HewlettPackard’s printer production division may choose tocollect all factory overhead costs in one cost pool and allocatethose costs from the cost pool to each product using onepredetermined overhead rate.

Again, notice that dividing fixed manufacturing overhead by number of units makes the gross profit for the deluxe purse significantly higher than if fixed manufacturing overhead is allocated according to direct labor. By allocating fixed manufacturing overhead by machine hours, the deluxe purse is actually costing more to produce than it is selling for. Let’s say we consider our operation to be labor-intensive rather than capital-intensive (automated).

By integrating this rate into financial analysis, firms can make informed choices that align with their economic objectives and operational capacities. The calculation of the plantwide overhead rate first requires gathering the following information. What sets Sourcetable apart is its ability to not only display results in the spreadsheet but also explain the computation in a chat interface. This dual approach enhances understanding, making it ideal for educational and professional settings. Whether studying for exams or preparing financial reports, Sourcetable ensures you achieve accurate and reliable results every time. Once we have determined our allocation rate, we apply that rate to each product or product line in order to assign costs to individual items or batches.

As the name implies, these overhead rates take into account the entire plant and not a particular segment or department. The plantwide overhead rate might not help obtain exact figures, but the estimates are efficient enough for better planning. Notice that under this allocation method, using direct machine hours instead of units, we have a dramatically different outcome. Under this allocation method, it looks like the deluxe purse is actually losing money. The calculation of a product’s cost involves threecomponents—direct materials, direct labor, and manufacturingoverhead.

For product-specific calculations, if Product A requires two labor hours per unit, the total overhead rate per unit would be 2 hours multiplied by $67, equating to $134 per unit. It means the total number of direct labor hours is taken as the denominator, which is divided the main advantage of the plantwide overhead rate method is: by the numerator as the total overhead cost of the company. Employ this calculation to enhance transparency and consistency in your overhead allocation. In response to this situation, manufacturers will use departmental overhead rates and perhaps activity based costing.